Interview Part 3: Great Graticules!

Part 3: Great graticules

More projects, reprints and prototype notes...

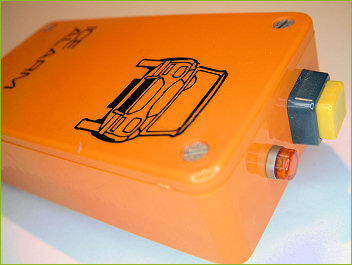

Uniboard Ice Alarm - January 1981. The Letraset car added by EE was a Citroën Ami. I used orange BIMboxes a lot. In Part 2 I explained the background behind my early projects that I’d started to submit for publication in Everyday Electronics. I continue with the story of more constructional projects and series, including the popular Uniboards that some readers still remember to this day. I’ve made downloadable PDF reprints of the articles with a separate PDF about my actual prototypes, which I’ve rediscovered and photographed again for the first time in 30-odd years.

Uniboard Ice Alarm - January 1981. The Letraset car added by EE was a Citroën Ami. I used orange BIMboxes a lot. In Part 2 I explained the background behind my early projects that I’d started to submit for publication in Everyday Electronics. I continue with the story of more constructional projects and series, including the popular Uniboards that some readers still remember to this day. I’ve made downloadable PDF reprints of the articles with a separate PDF about my actual prototypes, which I’ve rediscovered and photographed again for the first time in 30-odd years.

EE’s Editor Fred Bennett was kind enough to compliment me on my prototype quality and standards of presentation, and I suppose that what I lacked in circuit design expertise I made up for on the construction and writing side of things.

Barely out of my teens I’d made one or two tidy lump sums from my writing that I ploughed back into my hobby (which was becoming a bit of a part-time job), starting with a British-made Scopex 4S6 oscilloscope purchased from Maplin in the late 1970's. Having a home delivery by Securicor was unheard of back then, and an oscilloscope being delivered by a security firm made me feel very grand. In fact my Dad collected the ‘scope from Securicor’s local depot. There was a With Compliments slip inside as Maplin had fitted a mains plug for free – hard to imagine now, but back then you never got mains plugs with anything, so you fitted your own and hoped you’d wired it properly and chosen the right fuse rating.

I would often let the single-beam Scopex run just for the sake of it, its blue beam scanning across the graticule incessantly and lighting up my room.

I also started to buy some tools and I often doubled up on purchase orders for components, so I built up a small stock to draw from. Hence I have a lifetime’s supply of ½W carbon resistors, BA non-metric fasteners, hookup wire and 9V battery snaps.

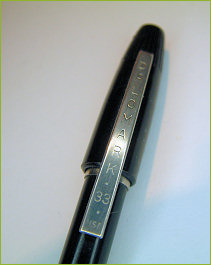

The Dalo Etch Resist Pen was a staple member of every hobbyist's armoury. There was also a red UV-proof version for touching up UV artwork. By now I was starting to gain confidence dealing with basic electronic circuits, developing and breadboarding ideas, manually devising the stripboard layouts, building prototypes and writing them up by hand. I started to explore the basics of TTL and 4000 CMOS logic and I also toyed with p.c.b. production, manually etching basic boards using a Deco Dalo etch resist pen in a tray of etchant on the back doorstep. I learned how ferric chloride stained concrete and some of my paperwork bears ferrous-stained fingerprints to this day.

The Dalo Etch Resist Pen was a staple member of every hobbyist's armoury. There was also a red UV-proof version for touching up UV artwork. By now I was starting to gain confidence dealing with basic electronic circuits, developing and breadboarding ideas, manually devising the stripboard layouts, building prototypes and writing them up by hand. I started to explore the basics of TTL and 4000 CMOS logic and I also toyed with p.c.b. production, manually etching basic boards using a Deco Dalo etch resist pen in a tray of etchant on the back doorstep. I learned how ferric chloride stained concrete and some of my paperwork bears ferrous-stained fingerprints to this day.

Getting bitten ever more by the electronics bug, age 19, in September 1978 I came up with an Extended Range Timer, based on the extremely interesting Ferranti ZN1034E timer chip. Remembering that I was entirely self-taught, I studied data sheets in more depth and would buy a small number of devices to experiment with

The ZN1034E intrigued me a lot, as it offered a highly accurate delay from seconds to months or years. I used one to drive a changeover mains relay with two mains sockets providing a Turn On or Turn Off mode, the first time I’d seen this ‘Normally off/ Normally on’ idea in use. Appearance was everything so I built it into an expensive-looking Verobox with smart anodised aluminium panel and spun aluminium knob. A BNC socket helped me calibrate it on my new oscilloscope.

It looked well, and was the first project of mine to be built on a printed circuit board: I remember handling the blue glass fibre board to this day.

Getting more exposure

By then I’d invested in a steel UV exposure unit (Maplin) and I believe the Seno GS Etch-In-A-Bag System (from Electrovalue, Maplin) arrived at that time too. In fact I bought a small hairdryer from Boots in 1978, to warm up the Seno polybag and accelerate the etching process! A few years later I wrote a series about Making Your Own PCBs in 1992, which included both my design for an artwork lightbox and the only photo of me ever to appear! Hoping that readers’ prototypes would work as described if they followed the plans meant that a bit of pressure and responsibility were ever present. In my Extended Range Timer I noticed a minor bug where mains spikes would sometimes reset the timer prematurely, a problem that I mentioned but never quite cured. My Extended Range Timer was published as “Mains On/Off Timer” but I was very surprised and disappointed that it took so long to appear – 16 months later in the January 1980 issue of Everyday Electronics. I was disappointed too that the project didn't make it onto the front cover. You can download the Extended Range Timer constructional project article and my prototype notes.

However Editor Fred Bennett seemed impatient to get the so-called Simple Transistor Designs (see Part 2) under way and so I sent off the first three articles to IPC in December 1978. They were (publication date in brackets):

- Time Delay Buzzer – a unijunction transistor firing a thyristor and buzzer (EE March ’79)

- Seconds Indicator – a transistor multivibrator flashing an l.e.d. (EE Jul ‘79)

- Burglar Alarm Module – a latching circuit with N.C. / N.O. loops (appeared as EE Dec. ’79 Uniboards #2) (see later).

I tried the new miniature vibrating reed buzzers that were arriving on the market and I used a neat low profile single-hole “Hekla” rocker switch that looked quite smart. In the event, the Time Delay Buzzer submission appeared as a standalone project renamed Time Delay Indicator in March 1979 EE (article) and the Seconds Indicator became a Darkroom Timer in July 1979 EE (article and two prototype notes).

The scheduling of everything all seemed a bit erratic to me. The Burglar Alarm Module didn’t appear until a year later, in December ’79 as part of my Uniboards series (No. 2), described later.

In due course communications with IPC Magazines got terribly out of hand, and I noticed that the magazine responses were backing up a long time by then. I frequently received apologies for the delays but IPC Magazines would sit on things for months, which became deeply disappointing and frustrating, taking the rewarding shine off my endeavours completely.

Uniboards (Simple Transistor Designs)

In early 1979 I followed up with more Simple Transistor Designs which I’d completed as fast as I could.

- Opto Alarm – an optically triggered thyristor and alarm (EE Nov. ’79) (article)

- Burglar Alarm Module – a N/O and N/C transistor/ thyristor circuit (EE Dec. ’79) (article)

- 9V Power Pack – a simple 9V unregulated power pack (EE Jan ’80) (article)

- Touch Switch – two MPSA14 Darlingtons latching a relay (EE Mar ’80) (article)

- Audio Oscillator – a unijunction oscillator crept in somewhere. (EE May 1980) (article)

- Voltage Converter – an emitter follower regulator with current limiting for in-car use (EE combined issue, June/ July ’80 – production slipped) (article)

- Dusk to Dawn Relay – a useful transistor Schmitt trigger, l.d.r. and relay (EE Oct. ’80). (article)

You can download all my Uniboards prototype notes, with photos of many original units, here.

By now, publishing lead times were slipping badly and the publication dates were quite ad-hoc. It all seemed to be in turmoil and as a 21 year old I was pretty despondent, given the pressure that they’d applied to get the material written to start with. It was also a tough time at home as I had to hold down a new day-job (I’d given up on accountancy and gone into industry) as well as helping to look after my Dad who became ill soon after we’d moved into a new family home.

Another full constructional article In-Car PSU using an LM317T and curly cigarette-lighter lead was submitted in May 1979, just a few weeks after we’d moved location. It was virtually the last constructional project to come from my original schoolkid’s “pioneering” physical roots before we moved house, and I had to finish it off at our new home. All things considered, I’m surprised that I managed to focus on it at all, looking back, and was very disappointingly the In-Car PSU didn’t appear until the April 1982 edition of Everyday Electronics, three years later! You can download the article and prototype details.

Our 1979 house move was intended to be part of a grander plan, but not long after moving, I would lose my Dad at the end of 1979 and I was left with a large new garage/ workshop to dink around in and other responsibilities too, but no-one to share my latest projects with apart from my Mum. The late 1970’s and 1980’s would be difficult times, but my Mum would often hear me drilling, soldering, bustling around or typing up my projects enthusiastically into the early hours, doing something useful and trying to earn money from my hobby. It was a very solitary job. I used the old estate agent’s For Sale folders as binders for my ideas and projects, and my enthusiasm and interest carried me through.

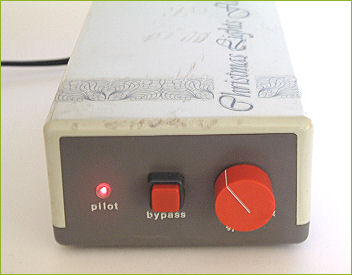

Christmas Lights Flasher December 1980One of the first projects produced under the new regimen was a Christmas Lights Flasher which I devised before 1979 came to a close. It contained a 555 driving a mains thyristor – quite scary stuff, sharing low voltage circuitry with the mains, but it worked fine on its printed circuit board. It was too late for the Christmas ’79 issue and appeared in December 1980 EE issue instead. You can download the original article and prototype notes.

Christmas Lights Flasher December 1980One of the first projects produced under the new regimen was a Christmas Lights Flasher which I devised before 1979 came to a close. It contained a 555 driving a mains thyristor – quite scary stuff, sharing low voltage circuitry with the mains, but it worked fine on its printed circuit board. It was too late for the Christmas ’79 issue and appeared in December 1980 EE issue instead. You can download the original article and prototype notes.

Looking back at those circumstances, I’m totally amazed at the sheer volume of manual work that I managed to get through, all done in tandem with having a day job while studying for exams at college too. There were no word processors or computers, so everything was drafted laboriously by hand and then typed on a manual Olivetti typewriter. Not until 1983 would I afford my first electric typewriter, a very noisy Silver Reed daisywheel machine. (A word processor was gifted to me in September 1990, an Amstrad PCW9512 costing £550.)

This lifestyle became the pattern of my worklife for very many years, having a day-job and then absorbing myself into my electronics out of hours, sometimes working to punishing schedules, but my hobby had developed into a rewarding second job that brought in extra income.

I continued with a variety of constructional projects, but it was hard work and not all of my efforts were a success. Like everyone else I had a number of rejects, and the lack of formal training prevented me from flourishing more.

At around this time I also took time off from work to study a Rockwell microprocessor course but despite my schoolboy interests in computer programming, I used up quite a lot of my annual holiday allowance before realising that writing machine code, and all that jazz, didn’t appeal to me much at all.

Gas Sentinel

My Uniboards were keeping me busy with several ideas on the go at once, but in September 1979 I’d also completed work on a simple Gas Detector based around a Figaro TGS solid-state gas sensor. Some fellow contributors had already had a go in other magazines and the idea had interested me a lot.

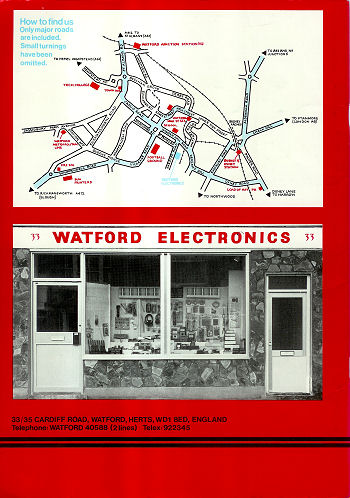

A variety of sensors were sold by Watford Electronics (whom I believe morphed into the IT reseller http://www.saverstore.com) that responded to carbon monoxide and various gasses. Here’s a cover shot of their 1978 catalogue…

Watford Electronics were a popular and well-known mail order supplier in the 1970's

Watford Electronics were a popular and well-known mail order supplier in the 1970's

... and had a shop that's still on Google Street View today … and 35 years later on Google Streetview you can see that the Watford shop has reverted to residential use – it’s a non-descript place in a sidestreet. The original mail order address was 33/35 Cardiff Road.

... and had a shop that's still on Google Street View today … and 35 years later on Google Streetview you can see that the Watford shop has reverted to residential use – it’s a non-descript place in a sidestreet. The original mail order address was 33/35 Cardiff Road.

I saw on Street View how the original crazy-paved shop window was still there in 2008 before being removed in 2009 onwards. The No. 33 property now appears to be two flats and No. 35 is a neighbouring house. Funny how full-page magazine adverts made suppliers look big. See https://goo.gl/maps/iDrjE8NpfNn In the latest Street View photos, if you zoom out an aerial view is adopted and outbuildings in the back yard can be seen. Perhaps they were the original Watford Electronics office or store.

For the Gas Sentinel I chose a basic and simple 741 comparator to trigger a thyristor, and I discovered a trick with a reset switch placed across the thyristor’s anode and cathode – you could close it to reset the SCR, and test the load at the same time. I liked the idea of space-saving dual-function controls. A mute switch silenced the buzzer, and sockets could drive an external sounder. A DIN socket connected the external TGS gas sensor, and an l.e.d. showed it was powered up.

Figaro's TGS sensor formed the heart (nose anyway) of my Gas SentinelThe Gas Sentinel (the magazine’s choice of title) was a compact, mains-powered unit and it turned out pretty well. In retrospect I realised that the Gas Sentinel wasn’t “intrinsically safe” but as a hobby project it would never be possible to make it gas-tight and sparkproof: there was the tiny risk that, in the event of a major gas leak, if you turned the alarm off a spark from the unit might cause an explosion!

Figaro's TGS sensor formed the heart (nose anyway) of my Gas SentinelThe Gas Sentinel (the magazine’s choice of title) was a compact, mains-powered unit and it turned out pretty well. In retrospect I realised that the Gas Sentinel wasn’t “intrinsically safe” but as a hobby project it would never be possible to make it gas-tight and sparkproof: there was the tiny risk that, in the event of a major gas leak, if you turned the alarm off a spark from the unit might cause an explosion!

IPC clearly liked the project because it was published rapidly, and appeared in April ’80 EE (constructional article and prototype notes). It was one of the more successful hobby projects of its type and it attracted a lot of interest along with a number of readers’ letters (unusually). It also found its way into marine use, with at least one yacht owner utilising it to detect gas leaks in the hull. He wrote to me using a BBC envelope, I recall.

Incidentally, in the same issue of EE there was news of Clive Sinclair launching his brand-new ZX80 home computer. In 1983 I would devise a Four-Channel version of the Gas Sentinel that was built on Veroboard**. I’ll describe that in a future part.

Gas Sentinel prototype 32 years onLooking back, my enthusiasm and focus probably overshadowed the need to take a commercial view, but it felt like I was trying to keep a hungry machine fed with proposals, articles and prototypes. A torrent of correspondence flowed to and fro, laboriously typed on a typewriter and posted in the mail, with steady pressure maintained to deliver the goods on time. A steady flow of pocket money came in.

Gas Sentinel prototype 32 years onLooking back, my enthusiasm and focus probably overshadowed the need to take a commercial view, but it felt like I was trying to keep a hungry machine fed with proposals, articles and prototypes. A torrent of correspondence flowed to and fro, laboriously typed on a typewriter and posted in the mail, with steady pressure maintained to deliver the goods on time. A steady flow of pocket money came in.

The early 1980’s brought a succession of modest constructional projects: after all, I got the same page rate whether the project was simple or complex, so I tried to produce smaller but well presented designs and the magazine frequently said how good they (and the manuscripts) were. Generally, I started to take a more business-like approach to my work, learning to organise myself properly and things seemed like a production line at times! Projects started to go through ‘on the nod’ as a matter of routine, which is one reason why outsiders found it hard to break into the market.

Next, a simple Soil Moisture Monitor gave a red/ green indication of soil, using brass rods as probes, and appeared in Nov. ’80 EE (article and prototype). It reflected my interest in gardening and greenhouse-keeping: there was a lot of that going on in our new house!

A follow-up series of IC Uniboards projects followed, containing a single integrated circuit. At least they were published in consecutive months for a change. I’ve reprinted the projects in PDF form and think they are still buildable today.

- IC Uniboards 1 – No Entry Indicator (a 555 flasher!) (EE Dec. ’80) (article)

- IC Uniboards 2 – Car Ice Alarm (CD4047, thermistor) (EE Jan 81) (article)

- IC Uniboards 3 – PSU (LM317H, multi voltage output) (EE Feb ’81) (article)

- IC Uniboards 4 – Mini Siren (NE556 and speaker) (EE Mar. ‘81) (article)

My prototype notes for the IC Uniboards series are here (PDF).

My hunger for more “column inches” was undiminished, and in Part 4 of my home-spun biography, more projects are described including another variable power supply – this one offering “All the Power You Need”. I’ll also look at some of the landmark Teach-In series that I worked on, and coping with changes at the magazine too.

** About ten years later, the publishers forwarded to me a typewritten letter from someone in India imploring them to put him in touch with me. He wanted updated plans for a multi-channel gas detector device that he could manufacture in Bombay. It turned out that my Bombay correspondent was a former polio victim who ran a small electronics operation from home, and before you knew it a Bank of India bank draft arrived in the mail to pay me in advance for the work. It was absolutely true to say that he ‘trusted me as an Englishman’ and he said as much. I reworked the article and devised the upgrades and wrote a manual.

I was gratified to learn that he went on to make them successfully in India, managing to open a small industrial unit in Mumbai later on, founded on my gas detector. We corresponded a few times as he proudly sent me photographs of his earlier achievement in athletics. I gather his son is now actively involved. Gratifying little moments like these made me feel that our fraternity was one big world family at heart, brought together more closely by the Internet.

Thursday, May 3, 2012 at 4:19PM

Thursday, May 3, 2012 at 4:19PM

Reader Comments